I Was Born for Dyeing

The following events take place between the hours of 1:00 a.m. and 5:00 a.m. on the day of April 19, 2009, and should not be repeated carelessly for fear of orange fingers and tired eyes.

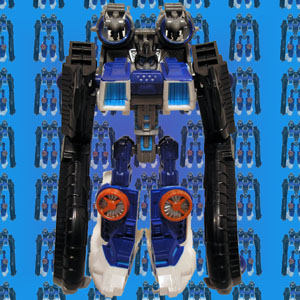

Having (for the most part) succeeded in dyeing soft resin munnies for the last six months, I decided to move to the next step: dyeing hard plastic transformers. Although the end results are somewhat less than perfect, I’ve learned a lot from the experience and hope to be able to correct the errors for the next test. But I figure it’s worth talking through and noting the problems, so that the next time is perfect.

Begin with the End in Mind

The test subject in question (Victim #1) was a Beast Wars Tigatron. The goal was to convert him to resemble the 1996 catalogue prototype, an orange tiger with green joints. Dyeing, if it worked, offered a quick, brush-stroke free, and scratch resistant approach to the outcome, turning his already light yellow plastic coat to orange. Although the neon green of the original Tigatron did not quite match the more forest green of the prototype, keeping the moulded green plast “natural” follows my traditional rule of leaving close colours alone (unless they really bug you).

The test subject in question (Victim #1) was a Beast Wars Tigatron. The goal was to convert him to resemble the 1996 catalogue prototype, an orange tiger with green joints. Dyeing, if it worked, offered a quick, brush-stroke free, and scratch resistant approach to the outcome, turning his already light yellow plastic coat to orange. Although the neon green of the original Tigatron did not quite match the more forest green of the prototype, keeping the moulded green plast “natural” follows my traditional rule of leaving close colours alone (unless they really bug you).

Really it was an ideal project for a first-time dye job. Nevertheless, like many projects, the big details are easy. The trouble is the smaller details, or the ramifications that comes from the big decisions.

Sharpen the Saw

For Tigatron, there were three such decisions that would have significant ramifications on the outcome:

For Tigatron, there were three such decisions that would have significant ramifications on the outcome:

1. Stripes: The question of stripes is important. Would Tigatron’s distinctive stripe pattern show through the orange or should I really get out the elbow grease and remove the patterns? Faced with hours of scrubbing, only to have to hand paint the details back on after the fact, I took the easy route and left the stripes intact.

2. Other Paint Applications: Tigatron has a fair bit of silver detailing, on his pelvis and lower knees and the eyes of his mutant head. Should this paint application be removed? I thought about this one too and decide that, instead, I would simply paint over the final results.

3. Green Joints and Parts: While Tigatron can be broken down fairly easily with the turn of a Philips screwdriver. But there are always parts that are not so easily removed. In Tigatron’s case, this includes the three straight metal pins at the shoulders and the tiger head joint. There is also instances where the original, making use of the predominant light yellow original plastic, has coloured sections to simulate the colour of the plastic, notably the arms and mutant head (both of which are glued into place) and the feet.

Be Proactive

Let’s talk paint applications first, specifically the arms. I did attempt to pry the arms away from Tigatron’s “skin”, but abandoned my efforts after stress began to appear. Given the less-than-likely prospect of success on the arms and head, I opted to simply dye the parts and colour correct later.

Let’s talk paint applications first, specifically the arms. I did attempt to pry the arms away from Tigatron’s “skin”, but abandoned my efforts after stress began to appear. Given the less-than-likely prospect of success on the arms and head, I opted to simply dye the parts and colour correct later.

Now while there is a great technique I’ve absorbed to remove these that consists of literally punching the pin out of the socket using a drill, I have never tried it. However, faced with the prospect of some of the green moulded plastic subjected to orange dye, I figured it was worth my time and effort.

I’m pleased to report that I’m confident the operation would have been a complete success had I not been rushing. As it was the neck and one of the arm pins fell out perfectly. However, I managed to crack the plastic joint on the second arm. I’ve sense learned that the break cannot be easily fix with crazy glue, as the stress of turning is too much for a repair.

Put First Things First

Break aside, I have successfully dismantled Tigatron. The water is boiled and the dye is stirred. And now I’ve dropped all the light coloured pieces into the pot, holding back on the green moulded plastic and the green painted feet (since the light plastic is minimal). The boiling water does its job and I am surprised at how quick and fulsome the job turns out. Removing the pieces and letting them dry, I allow myself to get exceedingly excited for the perfect custom.

It is not to be the perfect custom but unassembled at least, it is looking the part.

Think Win-Win

The first thing I check are the previous paint applications. The decision to leave the stripes and silver intact turned out to be an excellent approach. The strength of the orange dye was enough to turn the silver to a very pretty natural gold that suited the character. There was no need then to recolour these sections. And the original stripes showed right through the new orange coat. I then turn to the arms. The green paint has turned a lovely forest green… exactly the colour depicted in the catalogue.

I then make an understandable but stupid mistake. I change my plans without proper preparation or anticipation of error.

Seeing that the painted plastic turned the perfect colour of green, I got carried away and presumed that dyeing the moulded plastic would have the same result, and spur-of-the-moment decided to dye the rest of the pieces as well.

Seeing that the painted plastic turned the perfect colour of green, I got carried away and presumed that dyeing the moulded plastic would have the same result, and spur-of-the-moment decided to dye the rest of the pieces as well.

They turned brown.

Now this is not necessarily a bad thing. The brown actually looks better than green and again, the arms and head can be colour corrected with paint. And the rash act even allowed me to do the feet. The problem was not the decision to dye the moulded plastic, but that the approach negated any advantage gained from removing the three pins. It made the sacrifice of the break irrelevant and would have another unforeseen consequence for reassembling, the inevitable next step.

Suffice to say, while it is good to be flexible to change plans, one should always be aware of the full consequences of the changes. A change is suppose to make things better and not worse.

Synergize

So now the (very late at this point) moment of truth. Some assembly required. Screwdriver at the ready, I begin to reassemble the parts, a tricky job because there is always an order to things that can be problematic to remember. With the usual false starts I quickly find the resulting problems.

So now the (very late at this point) moment of truth. Some assembly required. Screwdriver at the ready, I begin to reassemble the parts, a tricky job because there is always an order to things that can be problematic to remember. With the usual false starts I quickly find the resulting problems.

We already discussed the issue of the arm joint crack and the different coloured green base paints. What I’ve not mentioned yet is that the plastic has warped from the heat. In some places it is just enough to cause some trouble with reassembly or resulting in a few gaps here and there. But in three key areas it is a disaster.

The first two are the legs. The lower legs just do not recombine anymore. Instead it is a painful and forced exercise, one that requires scraping to ensure the foot can be

The first two are the legs. The lower legs just do not recombine anymore. Instead it is a painful and forced exercise, one that requires scraping to ensure the foot can be

reinstalled and leaving a vertical gap straight down each lower leg.

The third disaster is with respect to the tiger head, where the side pieces have warped inward, making it difficult to reinstall the pin and joint.

A pin and joint that, in hindsight, I should not have removed given the decision to eventually throw everything into the dye.

In the end, the figure stands. But it is a forced effort, one that does not bold well for transformation. But there are lessons to be learned.

Seek First to Understand Then Be Understood

So where do I stand? Well, here is where I can  claim victory on the exercise:

claim victory on the exercise:

- Successful attempt at popping a number of pins;

- Successful colour dye of hard plastic.

Lessons learned? Areas for further research? Well, I’d have to say here:

- My next attempt, I will not dismantle the arm and tiger head brackets, unless I intend to leave them green. Which I might.

- Try reducing the temperature of the water to prevent warping, or try keeping the complicated pieces like the legs and the head (easy enough if the joint is left intact) together.

With TFCon coming up, I’m in good shape to pick up another guinea pig or three (perhaps with weapons this time!), or even a broken one that will allow me the chance to salvage Victim #1. That would be swell too. Anyway, an interest exercise all told. Thanks for reading.